Transforming Vyon® materials into simple and complex products is no challenge for Porvair Sciences. With over 70 years of experience in the manufacture of advanced porous plastics, we have a wealth of knowledge in how to manufacture products to high specifications.

Our diverse and state-of-the-art manufacturing capabilities allow us to support our customers with a variety of different product options.

In addition, our manufacturing flexibility not only allows us to supply custom products manufactured from sheet or roll materials, but also mould porous plastics into complex shapes to suit your needs.

Looking for support assembling your device? In partnership with our sister companies, we can offer fully assembled product solutions.

Our range of Vyon® porous plastics can be manufactured in widths up to 1060mm and in lengths bespoke to our customer requirements. We also offer a standard product range of 1m x 1m sheets in many of our materials. Sheets can be cut down to size or welded together to meet your needs.

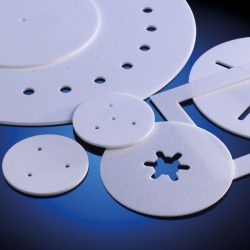

With a wide variety of disc cutting process’ available, we can convert Vyon® porous plastic rolls into discs and washers in sizes ranging from <3mm to 100mm.

Both our rotary cut and punched discs have excellent edge finish, which along with their rigid material properties, makes them ideal in automated product assembly.

Complex flat shapes which cannot be rotary cut, can be expertly converted with precision from Vyon® roll material using our state-of-the-art punching process. Vyon® punched shapes exhibit the same outstanding quality as our other cut products and are fully customisable to suit our customer’s requirements.

Using temperature CNC routing facilities offers a versatile way to create complex shapes. Our carefully monitored and enclosed manufacturing area ensures even the tightest of tolerances can be maintained over the largest of dimensions. Various additional features such as holes or steps can be easily incorporated into the product design. This machining process enables us to create clean cut products with well-defined edges ensuring a good fit into components such as industrial scale process chromatography columns and filter housings.

Our state-of-the-art Vyon® moulding facility allows for simple, complex and intricate component manufacture. We offer an elevated level of design from a large selection of material options. Our moulding expertise allows us to offer moulded products in varying levels of complexity; shapes may vary from simple pipette tip filters or sample preparation frits to highly complex shapes.

Vyon® roll and sheet material can be fabricated to create alternative 3D shapes including cones and tubes. Tubes are expertly seam welded and can be supplied with additional features such as end caps or adaptors. Our many years of experience make us world experts in products such as fluidising cones for the powder handling industry. The rigid and self-supporting Vyon® is fabricated to your custom cone design and can incorporate design features such as flanges, spouts and ribs.