While our original industrial Vyon® patents date back to the 1950’s, we have continued to strive and be at the forefront of new porous plastic technologies. Working collaboratively with our customers ensures our Vyon® materials are engineered to meet the tight technical specifications required from a wide variety of industrial applications.

Our Vyon® porous materials enable closed environments to breathe in critical applications such as venting of lead acid batteries. The controlled pore size, strength and inertness are key properties to achieving desired results.

Vyon® battery vents are typically supplied in the following geometries but are fully customisable to your requirements.

At Porvair Sciences, we have exclusively developed our own range of pneumatic silencers.

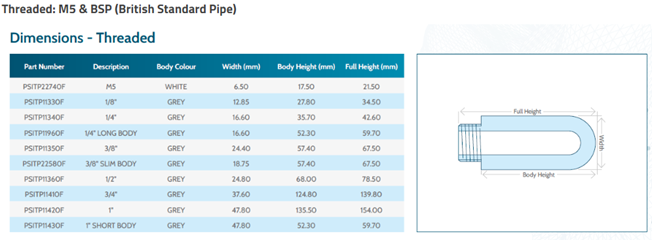

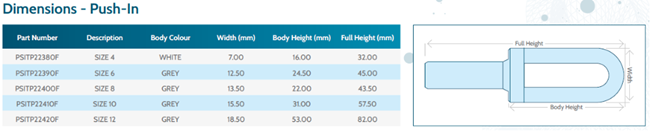

Available as a standard item, Vyon® silencers come in a wide range of sizes and formats with zero tooling costs. Please see below for more information

Alternatively we can offer our Vyon® silencing materials as fully customisable components, please contact a member of our team who will be happy to collaborate and find the perfect solution to meet your needs.

The Vyon® silencer is a sintered polyethylene body moulded to a high density polyethylene adapter. Available in push-in and threaded formats, the silencers are designed to significantly reduce noise without compromising air flow. The silencer is directly attached to the exhaust port of a control valve. The exhausting air escapes to the atmosphere by expanding through the porous body. The noise from a single unsilenced exhaust port is reduced from about 90 decibels to between 60 and 70 decibels when fitted with a Vyon® silencer.

Materials of Manufacture

Body: Vyon® sintered porous HDPE

Adapter: Injection moulded solid HDPE

Fitting

M5, BSP (British Standard Pipe) and push in connections

Maximum Working Pressure

10bar (150psi)

Noise Reduction

Up to 30dB

Operating Temperature

From -70°C (-94°F) to +80°C (176°F)

Only silencers purchased from Porvair Sciences or one of our distributor network can be verified as genuine Vyon® silencers. Please contact us for more information.

Only silencers purchased from Porvair Sciences or one of our distributor network can be verified as genuine Vyon® silencers. Please contact us for more information.

The good durability and smooth surface structure of Vyon® porous plastic make it an ideal material to use a vacuum table cover. Vyon® vacuum table covers hold down materials and allow precise cutting whilst maintaining a robustness to prevent excessive scratching of the surface.

Vyon® vacuum table covers are typically supplied in the following geometries but are fully customisable to your requirements.

Our Vyon® materials deliver optimum filtration in a wide range of industries for both liquid or gas applications. Vyon® offers rigid, strong, cleanable and reusable material to our customers. A highly desirable materials that is compatible with many industrial and process environments.

Vyon® filters are typically supplied in the following geometries but are fully customisable to your requirements.

Our sintered porous Vyon® materials are ideal for wicking and fluid transfer applications. The media’s uniform porosity and tortuous pore structure with large void volume enables the encapsulation of fragrances or chemicals for emanation or controlled release.

Vyon® fragrance emanation materials are typically supplied in the following geometries but are fully customisable to your requirements.

Vyon® has a uniform pore structure giving an excellent total area fluidisation. Self-supporting and rigid the Vyon fluidising material can be supplied in sheets or fabricated into large cones, reducing the need for external support structures. Vyon® fluidising material is economical and fully cleanable for multiple uses.

Vyon® fluidising media is typically supplied in the following geometries but are fully customisable to your requirements.

The reliable Vyon® porous polyethylene disc and tubular diffusers are used in sewage and industrial waste water treatment and can be custom manufactured in a variety of diameters and lengths. They produce uniform bubble size and pattern to ensure effective oxygenation and a long service life.

Vyon® aeration materials are typically supplied in the following geometries but are fully customisable to your requirements.